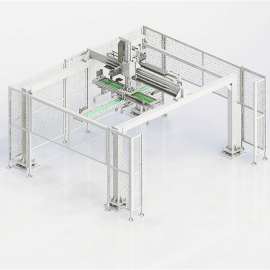

Function Introduction:

The cell induction soldering head is used to interconnect and solder the bus ribbon at the head, middle and tail of the outgoing line type assembly; it has the function of coil bus ribbon feeding belt and bending U-and L-type leads upward. Higher speed; compatible with larger size modules.

Characteristics:

- Cycle time 17s, high speed.

- Strong compatible with Multi-shard of 6 strings, 5 strings single bypass soldering and 6 strings double bypass soldering.

- Corrects twice to the position of the 10/12 series half piece cell string, grabs the cell string by vacuum adsorption, one time empty soldering and high welding accuracy.

- Convenient specification conversion

- Can punch at the end of the bus ribbon

- Single side feedback,easy to operate

- Double bypass soldering integration can meet the customer’s demand for 6 strings double bypass soldering of bypass bus ribbon, can be closed or opened according to the actual use demand.

- The smallest floor area, the lowest Co0.

Specification:

- Cycle time : 17sec/panel(single bypass soldering) 21 sec/panel(opening Double bypass soldering)

- Activation:98%;

- Cell Specification:166mm-230mm;

- Panel specification: A 156-180 Cell; 6 strings X 10half pieces X2;6 strings X11 half pieces X2; 6 strings X 12 half pieces

x2; 6 strings X 13 half pieces X 21 B,182 Cell; 6 strings X9 pieces X2: C210 Cell 6 strings X 10 half pieces X2; 6 strings X 15 one third pieces X2 D210 cell 5 strings X10 half pieces X2 : 5 strings X 15 one third pieces X2 - Cell space: -0.5-4mm;

- String space: 1-6mm; bypass soldering of string space :>10mm;

- Glass specification: width(980-1500)X length (1720-2600mm);

- Correction accuracy of cell string:<+025mm;

- Equipment power supply : three-phase 380V 50/60Hz;

- Power:Peak 35kw;; average 25kw;

- Air: positive pressure 0.6~0.8MPa, negtive pressure about-70kPa;

- Equipment size: length X width X height:6580 X 5604 X 2621mm(including two assembly lines)