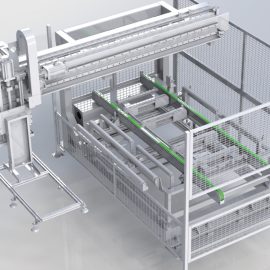

Function Introduction:

High temperature tape is used to seal the four sides of the double glass assembly before lamination

Parameter:

- Applicable components: conventional, half sheet and double glass components in length 1640-2500mm & width 950-1400mm

- Working beat: 22 seconds

- Maximum production capacity: 3,400 pcs / day

- Online operator: 0 people

- Rated power: 2KW

- Gas consumption: 60 L/min

- Pressure: 0.6-0.8MPa

- Interface specification: 12

- Overall dimension (length, X, width, X, height): 3,660 mm X 2500mm X 1650mm

- weight:1800KG

Advantage Introduction:

- Choose servo motor for high displacement accuracy and stability;

- The equipment includes the assembly leveling and fixing mechanism, with a total of 16 suction cups leveling out the components;

- The 16 suction cups are made of imported silicone material, and the equipment will not leave a mark on the surface of the component when working;

- The suction cup is designed as an integral integrated type, adjusted quickly, simple, convenient and reliable;

- The equipment completes the automatic operation without manual operation.

- Long and short edge change adjustment adopts quick locking mechanism, adjustment quickly, simple, convenient and reliable;